In today’s fluctuating construction market, burdened and uplifted by global economics, pricing swings, and varying trends in capital investment, there are few firms that can list 50 years in business on their list of accomplishments.

But Austin Metal Fabricators LP, a Burnaby based sheet metal business, is one of them. Austin Metal provides full service fabrication and installation of HVAC sheet metal and custom fabrication and architectural metalwork throughout the Lower Mainland. The company services commercial and industrial markets for renovation and new construction and builds from engineered drawing or through design-build services.

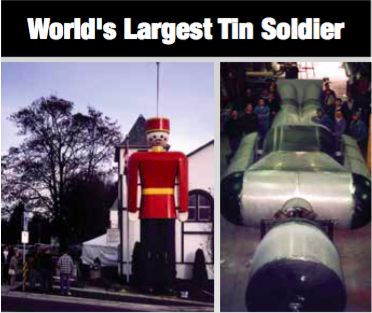

Austin Metal has been involved in some exciting projects over the years including the Shaw Tower, Fairmont Pacific Rim, Hotel Georgia, and the Poirier Sport and Leisure Complex. Dust collection systems, lab fume hood exhaust, ship work, and prisons are on its list of industrial project types, and condos, office buildings, hospitals, universities, and other commercial jobs round out an impressive professional repertoire. The company has always been a metal fabrication shop, which means its scope of work is diverse and includes custom metal work like the Tin Soldier in New Westminster at the quay.

But longevity and success haven’t come without effort and commitment. Austin Metal Fabricators was established in 1968 by Bill Gordon and Don Mueller. The shop was first located on Boundary in Burnaby, and two years later was re- located to it’s current location at 5414 Goring Street. As the business grew, new partners were brought into the ownership group. This provided Bill and Don with an exit plan allowing them to retire while still young and enjoy the adventures the world has to offer. The business is currently transitioning into it’s next stage of ownership through a staggered exit plan of existing partners.

The philosophy of the business has always been to do quality work at a fair price and provide excellent service, says Mark

Green, the firm’s senior partner. Guiding the customer through making the best possible buying decision is part of Austin Metal, he says. Sometimes that means helping to select the correct fan, equipment, choosing the right material to use, or, at times, changing the design all together.

“Always look at the project as if you were spending your own money,” he adds. “That is why we have so many repeat customers.”

Escaping five decades without challenges is nearly impossible, but Austin Metal has demonstrated the resilience and commitment to overcome anything.

“I think finding people with the right skill set and attitude is an ongoing challenge,” says Green. “Our diverse book of work requires highly skilled sheet metal workers so we spend a lot of time and money training our people.”

Because Austin Metal enjoys the benefit of a highly skilled work force, management is able to take advantage of the present market and choose which projects to pursue, rather than bidding every project that comes out for tender.

“I think the secret to our success is keeping the quality of our work at a high level, providing good service, and employing good people who care about what they are doing on a daily basis,” he says. “It is keeping the overhead as low as possible, and diversifying into new areas of the trade.”

The company has always aimed to remain current and diversify its scope as the market dictates. “It’s a slow process to try new things,” says Green. “Having the time to pursue new work is a challenge. You want to look after your existing good customers, do quality work all the time, and do it on time. No one wants to wait for too long.”

Looking ahead to the next 20 years, Green thinks the company’s biggest challenge will be skilled labour. He also sees important opportunities in HVAC construction and fabrication.

Austin Metal Fabricators constructed the iconic Tin Soldier, located in New Westminster on the quay, in 2000, as a fundraiser for the Christmas Festival of Trees. The statue is a replica of Sargeant Major Soldier, in honour of the Columbia Detachment of Royal Engineers’ role in establishing New Westminster.

The Tin Soldier stands at attention at 32 feet high, on size 60 E27 boots, weighing 10,000 lb. Austin Metal budgeted 500 hours for the soldier’s creation, which was an excellent approximation as the project came in at 510 and 3/4 hours. In 2002, it was distinguished by the Guinness Book of World Records as the World’s Largest Tin Soldier. It has gained international attention over the years.

Within the heart of the Tin Soldier resides a time capsule that will be opened in 2025, providing a new generation of New Westminster residents with a unique taste of local history.