In many cases, installation is just as important to louver function as is design. Specifying the correct frame style and options can substantially improve installation. In many cases, louver manufacturers have specific models and accessories to make installations faster and easier.

In many cases, installation is just as important to louver function as is design. Specifying the correct frame style and options can substantially improve installation. In many cases, louver manufacturers have specific models and accessories to make installations faster and easier.

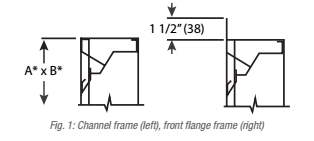

Louvers generally connect to surrounding structures through their perimeter frames. The most common types of frames are

flange and channel (Fig. 1).

Channel frames provide a consistent outside dimension around a louver’s perimeter. They do not extend beyond the overall width and height of the louver. For installation flexibility, they are the most versatile. They can be installed flush with the face of a wall, inset from the face, or slid inside a sleeve.

Flange frames are channel frames with one leg longer than the other. Flange lengths usually are 1 to 11⁄2 inches. Front flanges are the most common style; however, rear flanges are also available. The installation of flange frames is limited to flush mounts outside of a wall. Front flange frames help hide inconsistent gaps between louvers and the openings caused by uneven sizes or out-of-square conditions. The most common louver-installation method uses fasteners in surrounding walls or structures. In masonry walls, concrete screw anchors often are used. For metal structures, self-drilling metal screws are common. Lag bolts are used for wood frame installations. While manufacturers’ specific installation instructions should always be followed, a common fastener location pattern is 6 inches from the corners and 12 inches centre-to-centre on all sides.

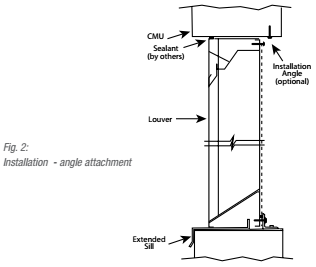

If a louver is small and the blade spacing wide enough, fasteners can be installed directly through the web of a jamb frame into a wall. However, if blade spacing is too narrow or a frame has downspouts that channel rain water, the installation of fasteners directly through a jamb should be avoided. This is the case with most wind-driven louvers. In such cases, installation angles can be utilized to connect the rear of a frame to an opening (Fig.2). For louvers with blade supports, angles should connect the tops and bottoms of the supports to a structure. Angles typically are provided as clip angles, which are 2 to 4 in. in length. They also can be supplied in full lengths for each side of a louver. These are known as continuous angles. Continuous angles cost more because of the material, but are faster to install. Installation angles can be used with channel or flange frames.

Some louver installation methods do not require the use of fasteners in walls. These methods often are time savers for contractors. One example is a sleeve with a retaining angle. This installation style utilizes front flange frames, perimeter sleeves, and continuous angles for the rear. The sleeved louver is slid into the opening from the front. Then, angles are installed to the rear of the sleeve with one leg against the wall. The other leg is fastened to the sleeve with screws. The flange and angle secure the louver tightly to the wall without the need for anchors, saving substantial installation time.

Some louver installation methods do not require the use of fasteners in walls. These methods often are time savers for contractors. One example is a sleeve with a retaining angle. This installation style utilizes front flange frames, perimeter sleeves, and continuous angles for the rear. The sleeved louver is slid into the opening from the front. Then, angles are installed to the rear of the sleeve with one leg against the wall. The other leg is fastened to the sleeve with screws. The flange and angle secure the louver tightly to the wall without the need for anchors, saving substantial installation time.

A louver-installation method is responsible for more than just holding a louver’s dead weight in a surrounding structure. It also must secure a louver during high wind conditions in severe storms. In applications with extreme wind loads, it is a good idea to specify the submittal of structural calculations from a registered structural professional engineer. Another way is to select louvres that bear a third party certification such as Underwriters Laboratories. Listings/approvals are for both louver and installation method.

No matter how effective a louver is in preventing rain penetration, water will find its way into a building if the installation is not properly caulked. First, the joint between the perimeter frame and opening must be sealed with backer rod and caulk. In flange frame applications, apply caulk around the flange perimeter and the wall. In addition to perimeter joints all other joints should be caulked.

By incorporating the louver features and proper installation practises, designers and installers can benefit from easier installation and better performance of their louvers.