Students recognize the value in skilled trades and see HMSE as an essential way to evaluate whether the trades are right for them

By / Jessica Kirby • Photos courtesy of McKinstry

Students from Highline Public Schools in the Seattle area participated in McKinstry’s Heavy Metal Summer Experience this past summer. Over six weeks, 15 students spent full days at McKinstry’s fabrication shop, learning the basics of sheet metal, plumbing, piping, and HVAC service, and what it takes to build a long, successful career in the construction and energy industries.

McKinstry hosted the event to invest in a strong, skilled future work force. Introducing students at the high school ages has proven the sweet spot for garnering interests in the skilled construction trades. Ultimately, McKinstry aims to spark excitement in the next generation of innovators.

Heavy Metal Summer Experience is a hands-on, day (or weeks) in the life program developed by by the Bay Area SMACNA chapter in collaboration with SMACNA-Western Washington. Its length and structure ensure an immersive experience in which students go beyond learning hands-on skills to practice critical thinking, problem-solving, collaborating, and developing the specific technological and interpersonal abilities needed in the construction trades.

McKinstry’s skilled tradespersons led 2.5-hour training sessions which involved projects, networking with industry professionals, a tour at the Local 66 JATC, a visit to an active job site and a graduation ceremony celebrating the team’s accomplishments.

Participants received personal protective equipment, work boots from Red Wing, and tool kits from Milwaukee Tool. They were also briefed on safety procedures and took a safety-specific tour of the shop to review best practices and procedures. The school district provided transportation to and from the various training areas.

Students visited Local 32 Plumbers, Pipe Fitters, Refrigeration & HVAC Union and Local 66 Western Washington Sheet Metal JATC, where they toured the facilities, were introduced to equipment used in the field, learned about steps to becoming an apprentice, and constructed projects with guidance from program instructors and current students.

In the plumbing portion, students became familiar with the skills required to work in the trade, tool safety, and constructing a picture holder and jewelry stand from copper pipe.

“At Local 32, I fell in love,” says A’Xavier Williams, a graduated senior. “I think that’s what I want to do.”

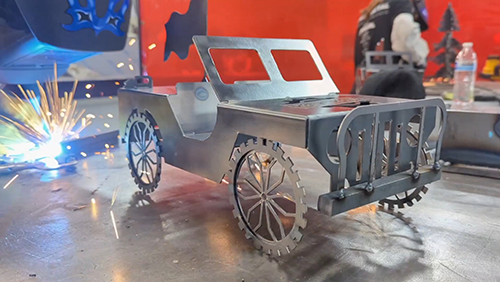

In the sheet metal portion, students reviewed tools, equipment, and safety, and constructed a trash bin and a toolbox. The projects were deliberately linked to information delivered at the Local 66 JATC, allowing the students to showcase their knowledge.

Over the final weeks, students experienced real-life work experience and explored McKinstry Service, which provided essential insight into the daily lives of service HVAC and plumbing technicians. They also toured the active jobsite the University of Washington Power Plant.

The program ended with a brief look at the pipefitting trade where participants learned how to read project designs to construct a threaded pipe shelf.

“I’m proud of everyone involved and the work going into this opportunity for these students to explore what we do here at McKinstry and what the industry and trades are really like,” says Adam Campbell, McKinstry’s superintendent of new construction mechanical. “We had a great time working with the students over the last few weeks!

“The first few meetings were focused on plumbing, then the participants were taken on field trips to experience the training our apprentices receive in plumbing, pipefitting, refrigeration, and sheet metal. The students were very engaged and asked great questions.”

Students attended HMSE for a number of reasons. Josh, a graduated senior, says he was interested because his family members work in the trade.

“I have always had an interest in construction,” he says. “Plumbing has been my favorite. I see myself joining a trade but haven’t decided which one. I want to see what options I have.”

Others, like Subeg Dhillon, a graduated senior, were interested in skill development. The project portion and time in a professional shop were highlights for Dhillon.

“I like welding and working with my hands,” he says. “Doing it with groups is more fun, and it builds friendships and bonds. Learning new skills, you become a better person.”

Dhillon adds, “The projects have been fun. You can mess up and have a little laugh, but I felt like it made me learn more about the outside world. Getting a little experience in a workplace could give me more opportunities for the future.”

HMSE has proven itself a valuable recruitment tool and practical, hand-on immersive experience for students who are curious about trades, as shifts in education occur and more students seek career alternatives to university and college.

Contractors and JATCs looking to host HMSE camps are supported by the HMSE Playbook, a living document manual that outlines sample camp schedules, parameters, projects, and instructional tips. ▪

Johansen Hosts Second Heavy Metal Summer Experience

Over the next five years, 40% of the construction workforce will retire. This, on the heels of a record-breaking labor shortage, has contractors in all areas of construction wondering how they are going to get their jobs done. Heavy Metal Summer Experience is one answer.

Angie Simon, former SMACNA president and CEO of Western Allied Mechanical, is co-founder of HMSE, along with Hermanson in Washington State. When the organizations piloted the six-week camps in California and Washington, respectively, they drew an impressive 28 participants. In 2022 (year two), 11 HMSE camps serving 170 kids popped up around America. And this summer, 22 camps, including Canada’s first, in Lancaster, Ontario, brought nearly 400 kids to sample the trades.

“From the beginning, the focus has been career exploration within the mechanical trades for high school students and recent graduates between 15 and 19 years old,” Simon says. “Participants complete projects, work alongside professionals, and learn about local apprenticeship training opportunities.”

With the intention of expanding and replicating the program across North America, the program organizers have created and continuously update the HMSE Playbook, a how-to manual complete with sample schedules, projects, and pro tips for hosting a camp.

This summer, Johansen Mechanical Inc. (JMI) hosted its second HMSE camp. The SMACNA-WW member company provided the organization, instruction, materials, and equipment to perform various projects at the JATC in Monroe, WA.

“Our employees find it rewarding to volunteer their time to mentor a graduating student and show them the opportunities available in our trade,” says Dan Moore, division manager at JMI.

The team enjoyed that the program laid out in the HMSE Playbook is flexible, but also specific for smaller companies who might not have the resources to dedicate to solely focusing on developing a camp.

For contractors looking to run their first camp, Moore recommends starting small until they have a process in place.

“I would start with a small group and expand each year,” he says. “You can get quite overwhelmed quickly if you don’t have the support to host 12+ students.” ▪