Northwest Sheet Metal had the human powered expertise and state of the art technology to pivot in chaotic times

By / Jessica Kirby • Photos courtesy of Northwest Sheet Metal

The words “agility,” “nimble,” and “pivot” have become commonplace these past several months, and in conversations about a new project from Northwest Sheet Metal this is no exception.

The Surrey-based contractor took on construction of battery and engine boxes for an electric vehicle powertrain prototype designed by powertrain engineering firm Litens Automotive, which is headquartered in Toronto, Ontario. The system was constructed as a one-off research and development platform that will be used to test new electric vehicle-focused products in the areas of thermal and battery management. University of Toronto will also use this vehicle as part of a joint battery research project.

“Today, everything is controlled by software, which is protected and would require source code and modification in order to do the kind of adaptation that we need,” says John Antchak, vice-president of Litens Automotive. Antchak is related to the owners of Northwest Sheet Metal but not affiliated with the company. “With this project, we started with an open source vehicle controller and built out from that. Everything in the vehicle is controlled by it, including the interior functions, lighting, steering, and others.”

The ultimate goal was a modern, first-class OE level electric powertrain, and the results have been outstanding. The ET187 is an all-electric truck built in house by the Litens’ engineering team. The prototype will start off as a new Ford Ranger 4×4 minus the standard powertrain and associated life support systems, which will be replaced by the electric system.

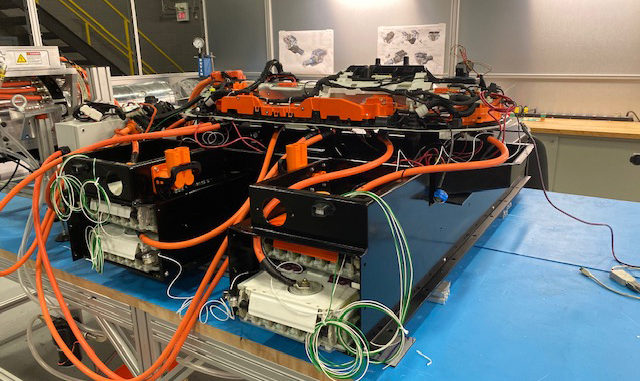

The heart of ET187 is a fully engineered low center of gravity lithium-ion battery system delivering 80 KWh capacity mounted under the floor between the frame rails. Muscle is provided by two three-phase AC PM motors in series taking in 400V through two inverters and delivering 840 Nm of torque to a single gear reducer and out to the original transfer case and rear axle system.

Keeping the simple and effective driveline was one of the developers’ targets and ultimately resulted in the unique and innovative battery case design that accommodates thepropeller shaft running through it.

Northwest Sheet Metal fabricated the battery case, battery management housing, and vehicle mounting system for the prototype. Four six-foot-long Tesla battery modules were extracted from a Tesla underfloor battery case and re-engineered to fit under the floor of the Ranger with the driveshaft for the rear wheels running down the center. Together, the batteries weigh 1,000 pounds.

“The battery case is complex with many precise dimensions to properly support the batteries and to fit into a very tight package between frame rails, rear axle, and transfer case,” Antchak says. “This required hard adherence to tolerances and precise craftsmanship.”

Considering road loads (bumps), cornering, potential impact, and stress from acceleration and braking, the battery system is under tremendous stress, which means it had to be fully validated through extensive computer modelling and simulation.

“The welding and forming have to be professional level to match the strength predicted by the computer models,” Antchak says. “The design and fabrication of this system was the hardest part of the truck project.”

Gord Gohringer, shop superintendent at Northwest Sheet Metal and Local 280 member, says because the project was a brand new idea, Litens essentially gave the team at Northwest a series of concept drawings that the team had to rework and confirm with the client.

“They weren’t exact, so we couldn’t just download them and begin fabrication,” Gohringer says. “We had to redraw the part and put it into the system to see if it would work. They knew the size and what they wanted, and we had to make it happen.”

The prototype’s uniqueness and the fact that it had zero tolerances presented a challenge for the team. “In CAD, the drawings are given sizes and allowances,” Gohringe said. “There was none of that. We had to make sure that the samples would work. It required special tooling, and eventually we had to make a bunch of samples to make sure we could even make it with zero tolerance.”

Having a cohesive, skilled labour and management team is what makes it possible to complete this kind of one-off, completely outside of the wheelhouse job, Gohringer says. It is what allows contractors to pivot on a dime.

“Because we are working in a union environment and trained by the union, we have the skilled workforce and management to adapt on the fly,” he says. “Without that kind of team, we couldn’t even begin to tackle something like this.”

Another factors is Northwest Sheet Metal’s readiness to adopt new technologies, making it one of the province’s most advanced in that capacity.

For starters, the company has a 20’ laser metal cutting table, complete with fully automatic 4 coil line feed, capable of cutting 1” thick steel with absolute precision. It runs a Full Iowa Precision 5’coil line, a Vulcan Waterjet Table, which provides a green initiative by reducing waste by over 80%, a 20’ Vulcan plasma table, and several other state of the art innovations.

“Northwest has invested in itself heavily with CNC technology, which opens doors that were never available before,” says Bernie Antchak, business operations manager for Northwest Sheet Metal. “We believe in it so much that we are looking to expand our detailing department even further.”

Northwest uses BIM and detailing on almost every project in some way—in fact, the company gets hired by other contractors to perform this task, as well, Antchak adds.

“We have all the latest in software and drawing programs and the talent here to use it all to its highest potential,” Gohringer says. “The more doors we can open with technology that gets us moving out of the same old routine, the more work and opportunity we can offer our union members.”

“It also helps to be connected to two guys who are not afraid to tackle tough jobs,” John Antchak says. “Many vendors were afraid to tackle this job due to tolerances and quality expectations.”

At the time of writing, the project had run eight months through the COVID period and involved the collaboration of over 60 people in different disciplines working on subsystem teams: battery, powertrain, chassis, and design. The result is a testament to the talent, commitment, and adaptability of this immense team and a nod to the future. ■