Coated fiber glass duct liners aren’t a new concept in the HVAC industry; however, we have seen a recent trend toward replacing specified coated duct liners with uncoated fiber glass mat-faced duct liners. This trend operates on the assumption that a mat-faced duct liner and a coated duct liner are equivalent and interchangeable.

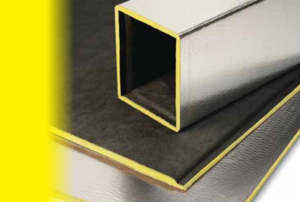

Johns Manville produces fiber glass duct liner with a durable, factory-applied coating on a glass-mat-faced airstream surface, as well as a duct liner with an uncoated glass-mat surface airstream, and is therefore uniquely positioned to compare the two products side-by-side.

Coated and uncoated duct liners each have features that make them uniquely appropriate for differing applications. While uncoated duct liners are a more economical solution that is appropriate for many applications, they do not offer the same, robust benefits that a coated duct liner does.

For example, our coated duct liners are all coated with a proprietary, acrylic coating with an EPA- registered anti-microbial agent that helps protect the coating from damage due to mold or fungi.

Despite the differences between the two products, many mistakenly believe that they can be used interchangeably. This is a risky misunderstanding that can leave an insulation system vulnerable to a number of hazards. Coated duct liners offer a host of features that can preemptively address these hazards, making them better suited to more demanding applications.

1. Durability: Most duct liners (coated and uncoated) have a glass-mat airstream surface to help provide a tougher, more resilient product. While the durable mat-facing on the air-stream surface does offer some level of protection against damage, the addition of a tough, acrylic coating over the mat- facing provides superior protection during duct fabrication, storage, transportation to the job site, installation, and throughout the operating lifetime of the HVAC duct system. Additionally, because the coating makes the duct liner more resilient, it can be cleaned more easily and effectively using industry-recognized cleaning methods (See North American Insulation Manufacturers Association’s (NAIMA) “Cleaning Fibrous Glass Insulated Air Duct Systems” for industry standard cleaning methods).

2. Moisture Resistance: Acrylic coating creates a water-resistant airstream surface that is an important element to an insulated duct system. While a properly installed and filtered system will reduce the risk of moisture ingress, there is still a likelihood that it could occur. When water enters the system, it can cause significant damage to a duct system, ranging from mold-growth to insulation damage. The coating helps keep the moisture on the surface of the insulation so that it can evaporate before it infiltrates into the core of the fiber glass.

3. Antimicrobial Product Protection: While fiber glass itself is inorganic and as such will not support mold-growth, when dust or dirt enters the system it can introduce foreign microbes into the ducts. If these foreign contaminants are coupled with moisture, mold or fungi growth may occur on any surface, even inorganic surfaces like fiber glass or bare sheet metal.

The first step in reducing the risk of microbial growth is to ensure that the system has been properly designed and installed, with effective filtration, maintenance, and operation; however, coupling this with a smooth surface and protective coating helps reduce the likelihood that dirt, pollen, and other foreign microbes and particles will become trapped on the air-stream surface of the duct. The EPA registered anti-microbial agent in JM’s acrylic coating also helps prevent mold spores and dirt from penetrating into the fiber glass mat and core, helping to ensure that the fiber glass isn’t compromised in places that are difficult and sometimes impossible to clean.

4. Improved Airflow: When a glass-mat surface is coated, it creates a smooth airstream surface that optimizes air-flow and reduces friction. This, in turn, ensures that the system is operating as efficiently as possible, and it reduces noise caused by friction between the surface of the liner and the air passing through the duct. Additionally, the coating provides extra protection to keep any loose fibers from entering the airstream.

5. Specification Compliance: When the specification contains language that expressly indicates the application should use a coated duct liner, an uncoated duct liner should not be considered as an equal to or alternative option. The engineer

who designed the system may have specified coated duct liners in order to meet code standards or to ensure safety or system optimization.

Fiber glass duct liners remain the most economical way to control noise and temperature in a duct system; however, the surface coating is an important feature in a lined duct system. Coatings can help prevent costly repair or replacement that could be required if the duct system becomes damaged by microbial growth. While cost, quality, and performance are critical to selecting and specifying HVAC duct liner insulation, it is crucial to consider whether the savings from using an uncoated duct liner outweigh the benefits that a coated duct liner provides.